Sentian Pet is based on natural materials, and its products are widely used in solid wood, sisal, seaweed, corn leaves and other environmentally friendly materials, which are deeply loved by customers and consumers.

The world of jewelry and gemology relies on precision and accuracy. From assessing the value of precious gemstones to creating intricate jewelry pieces, every detail matters. In recent years, the emergence of high-precision strain gauge sensors in mini jewelry scales has transformed the industry. These compact devices have brought a new level of accuracy and convenience to jewelers, gemologists, and even everyday users.

Jewelry, with its intricate designs and precious materials, demands precision at every stage of production and evaluation. Accurate measurements are crucial for various aspects of the jewelry industry, including:

Gemstone Grading: Precise weighing and measurement of gemstones are essential for grading their quality and value. The slightest variation in weight can significantly impact a gem's classification.

Metal Alloys: Jewelers use precise measurements to mix and alloy metals to create the desired quality and color of jewelry, such as white gold, rose gold, or platinum.

Design and Manufacturing: Creating delicate jewelry pieces requires accuracy in measuring materials, gem placements, and dimensions to achieve the intended design.

Pricing and Valuation: Accurate weight measurements are fundamental for determining the value and pricing of jewelry, whether for sale, insurance, or appraisal purposes.

High Precision Strain Gauge Sensors

Strain gauge sensors have long been a cornerstone of weighing technology. They work based on the principle that the electrical resistance of a material changes when it is subjected to strain or pressure. In the context of jewelry scales, high-precision strain gauge sensors are used to detect minute changes in weight and provide accurate readings.

The emergence of high-precision strain gauge sensors in mini jewelry scales has had several significant implications:

Submilligram Accuracy: These sensors can measure weights down to a fraction of a milligram, providing levels of precision that were previously challenging to achieve with traditional scales.

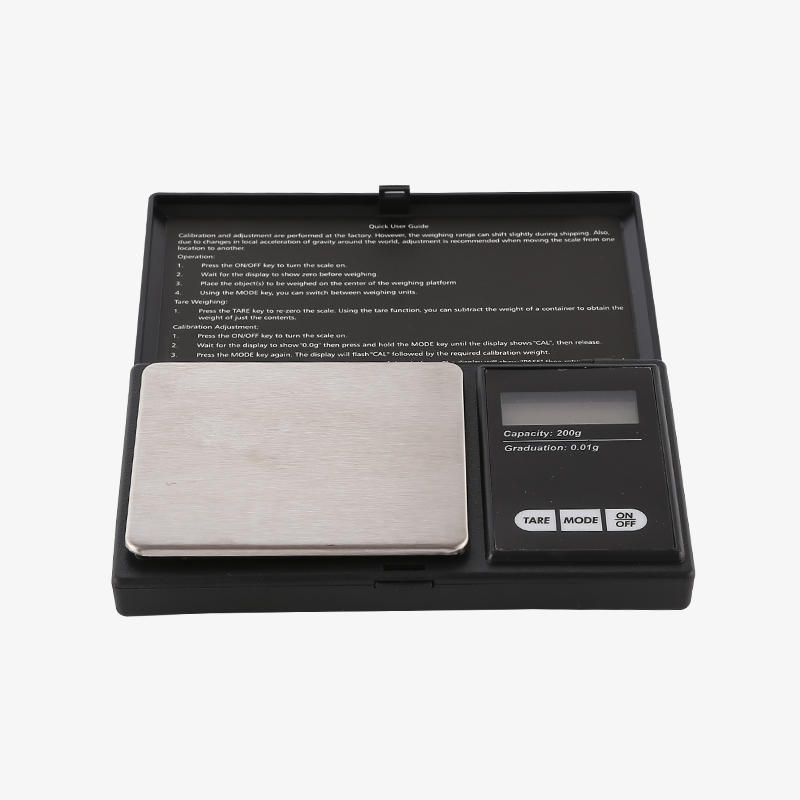

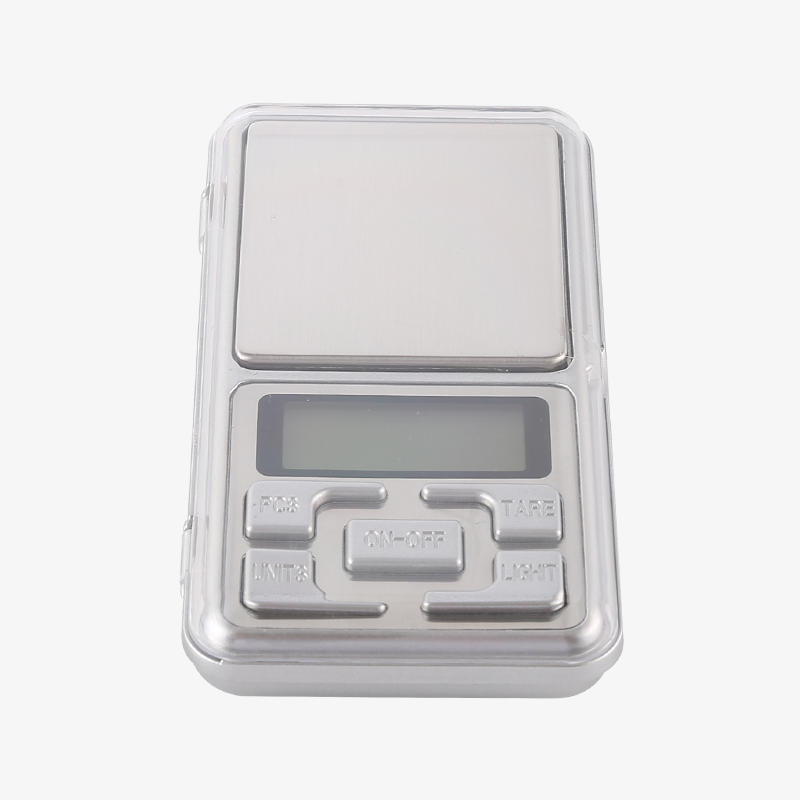

Compact and Portable: Mini jewelry scales equipped with high-precision strain gauge sensors are small and lightweight, making them easily portable and suitable for on-the-go use.

Quick Readings: The response time of these sensors is remarkably fast, allowing users to obtain weight measurements almost instantly, which is especially valuable in busy jewelry shops.

Tare Functionality: Many mini jewelry scales with strain gauge sensors feature a tare function, enabling users to measure only the weight of the item being assessed, excluding the weight of the container or tray.

Significance for Jewelers and Gemologists

The emergence of high-precision strain gauge sensors in mini jewelry scales has significant implications for jewelers and gemologists:

Enhanced Accuracy: These scales provide unparalleled accuracy in weighing gemstones and precious metals. Gemologists can confidently grade gemstones, taking the smallest weight variations into account.

Portability: Mini jewelry scales are ideal for gem shows, auctions, and on-site appraisals. Gemologists can easily carry them to various locations to assess gemstones or verify the authenticity of jewelry.

Cost-Effective: Mini jewelry scales with strain gauge sensors are relatively affordable compared to large, laboratory-grade scales. They offer an economical yet highly accurate solution for small-scale jewelry businesses and gemology enthusiasts.

Versatility: These scales can be used to measure a wide range of materials, from gemstones and metals to findings and components, making them a versatile tool in the jewelry-making process.

Increased Productivity: Fast response times and accurate measurements enhance productivity in the jewelry industry. Jewelers can expedite their work without compromising precision.

عربى

عربى Español

Español