Sentian Pet is based on natural materials, and its products are widely used in solid wood, sisal, seaweed, corn leaves and other environmentally friendly materials, which are deeply loved by customers and consumers.

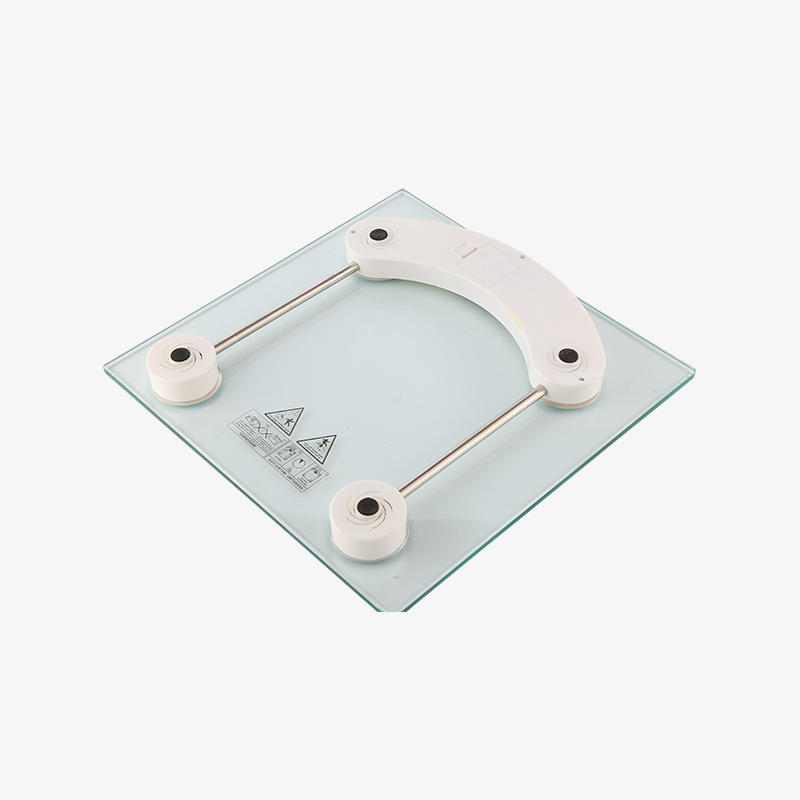

The demand for portable personal weighing digital bathroom scales has surged as individuals become increasingly conscious of health and fitness. However, behind the sleek exterior of these modern scales lies a complex production process fraught with potential challenges.

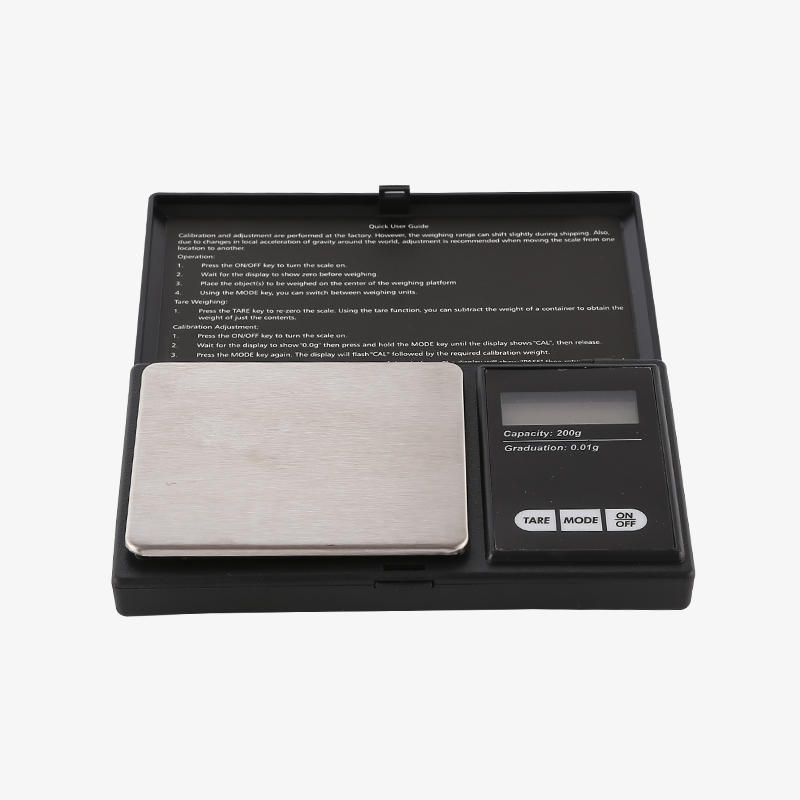

Calibration issues can lead to inaccurate readings, impacting the reliability of the scale. The precision required for personal health monitoring demands meticulous attention to calibration during the production process. Factors such as sensor accuracy, load cell calibration, and electronic circuit stability must be rigorously tested and calibrated to guarantee precise weight readings.

Material Selection and Durability:

The choice of materials plays a crucial role in determining the durability and longevity of a digital bathroom scale. Inexpensive or subpar materials can result in premature wear and tear, affecting the scale's overall performance. Issues such as cracked or discolored displays, worn-out sensors, or damaged load cells can arise if the materials used are not of high quality. Manufacturers must carefully select materials resistant to moisture, impact, and environmental factors to ensure the scale's durability over time.

Battery Life and Power Management:

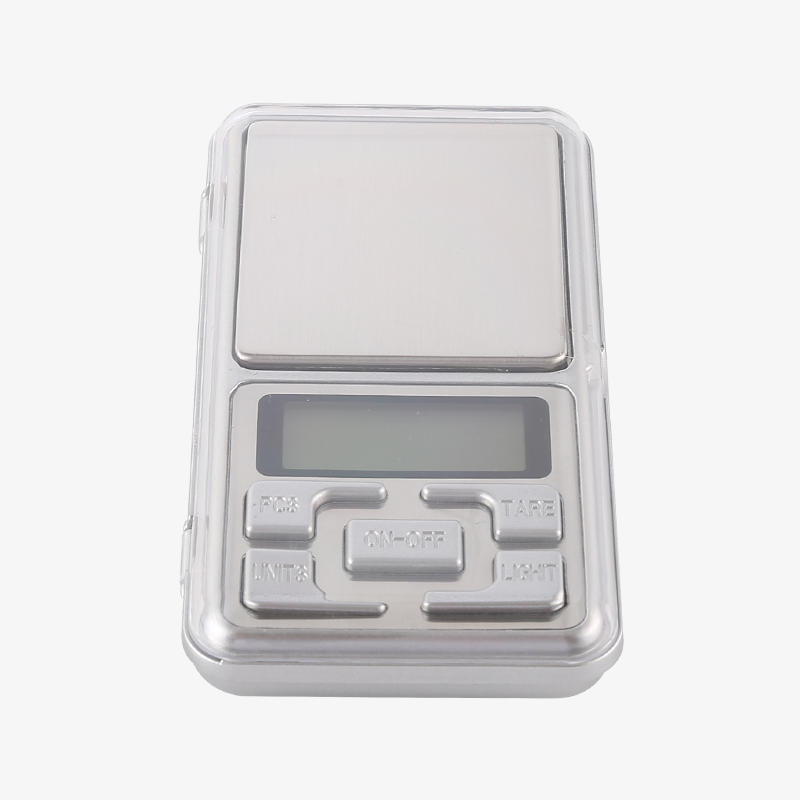

Portable personal weighing scales are typically powered by batteries, and managing battery life is a critical consideration. Inadequate power management can lead to frequent battery replacements, inconveniencing users and contributing to environmental concerns. Striking a balance between functionality and energy efficiency is essential in the production process. Implementing intelligent power-saving features, such as auto-off functions and low-power consumption components, can help extend the battery life and enhance the user experience.

User Interface and Display Issues:

The user interface and display are integral components of any digital bathroom scale. Problems related to the display, such as flickering, fading, or malfunctioning LED or LCD screens, can compromise the user experience. Inaccurate or non-responsive touch buttons can lead to frustration. Manufacturers must focus on the design and quality of the user interface components to ensure clear visibility, ease of use, and long-term reliability.

Bluetooth Connectivity and App Integration:

Many modern portable personal weighing scales come equipped with Bluetooth connectivity for seamless integration with health-tracking apps. Challenges may arise in the production process related to Bluetooth pairing issues, inconsistent data transmission, or compatibility problems with mobile devices. Ensuring robust Bluetooth connectivity and flawless integration with associated apps is crucial for providing users with accurate and convenient health monitoring features.

Production Consistency and Quality Control:

Maintaining consistency in production is a constant challenge, especially when producing electronic devices with intricate components. Quality control measures must be implemented at every stage of the manufacturing process to identify and rectify defects. Inconsistencies in production can result in variations in accuracy, reliability, or appearance, impacting the overall quality of the final product. Rigorous quality assurance protocols are vital to ensuring that each portable personal weighing scale meets the established standards.

Cost Management and Pricing Pressures:

Balancing cost-effectiveness with product quality is a perpetual challenge in the production of portable personal weighing scales. The pressure to keep production costs low may tempt manufacturers to compromise on the quality of components or materials, start to issues down the line. Striking the right balance between cost management and delivering a reliable, high-quality product requires careful consideration and strategic decision-making throughout the production process.

Market Competition and Innovation:

The market for personal weighing scales is highly competitive, driving manufacturers to continually innovate and introduce new features. Keeping pace with technological advancements while maintaining production efficiency is a challenge. Manufacturers must invest in research and development to stay ahead of the curve, addressing consumer demands for enhanced functionality, improved accuracy, and innovative features without sacrificing production stability.

The production of portable personal weighing digital bathroom scales is a delicate and multifaceted process that requires meticulous attention to detail. By prioritizing quality control, selecting high-grade materials, and embracing technological advancements responsibly, producers can overcome these challenges and deliver reliable, durable, and innovative digital bathroom scales that meet the evolving needs of health-conscious consumers.

عربى

عربى Español

Español