Sentian Pet is based on natural materials, and its products are widely used in solid wood, sisal, seaweed, corn leaves and other environmentally friendly materials, which are deeply loved by customers and consumers.

In the realm of industrial operations, the electronic crane weighing scale plays a pivotal role in ensuring accurate and efficient material handling. However, the reliability and precision of these scales hinge significantly on the materials used in their construction.

At the core of electronic crane weighing scales lies the load cell, a crucial component responsible for converting the force exerted by the load into an electrical signal. The material composition of the load cell directly impacts the scale's precision and accuracy. Common materials for load cells include alloy steel, stainless steel, and aluminum. Alloy steel is robust and durable, suitable for heavy-duty applications, while stainless steel offers corrosion resistance, crucial for environments where exposure to moisture or chemicals is a concern. The selection of load cell materials is a critical decision, influencing the scale's ability to withstand harsh conditions and maintain accuracy over time.

Scale Structure and Housing: Shielding Against the Elements

The overall structure and housing of the electronic crane weighing scale contribute significantly to its resilience and longevity. In industrial settings, these scales are exposed to a myriad of environmental factors, including temperature variations, humidity, dust, and potential impact. Materials such as stainless steel or aluminum are commonly employed for the scale's structure and housing due to their corrosion resistance and durability. These materials not only protect against the elements but also ensure that the scale maintains its structural integrity under heavy loads and challenging operating conditions.

Cable and Wiring: Transmitting Signals Reliably

The materials used for cables and wiring in electronic crane weighing scales are critical for reliable signal transmission. Copper is a commonly used material due to its excellent conductivity, but issues such as corrosion can arise over time, especially in corrosive industrial environments. In response to this challenge, manufacturers often utilize materials like tinned copper or corrosion-resistant alloys to enhance the durability of cables and wiring. This choice mitigates the risk of signal degradation, ensuring that the scale consistently provides accurate weight readings.

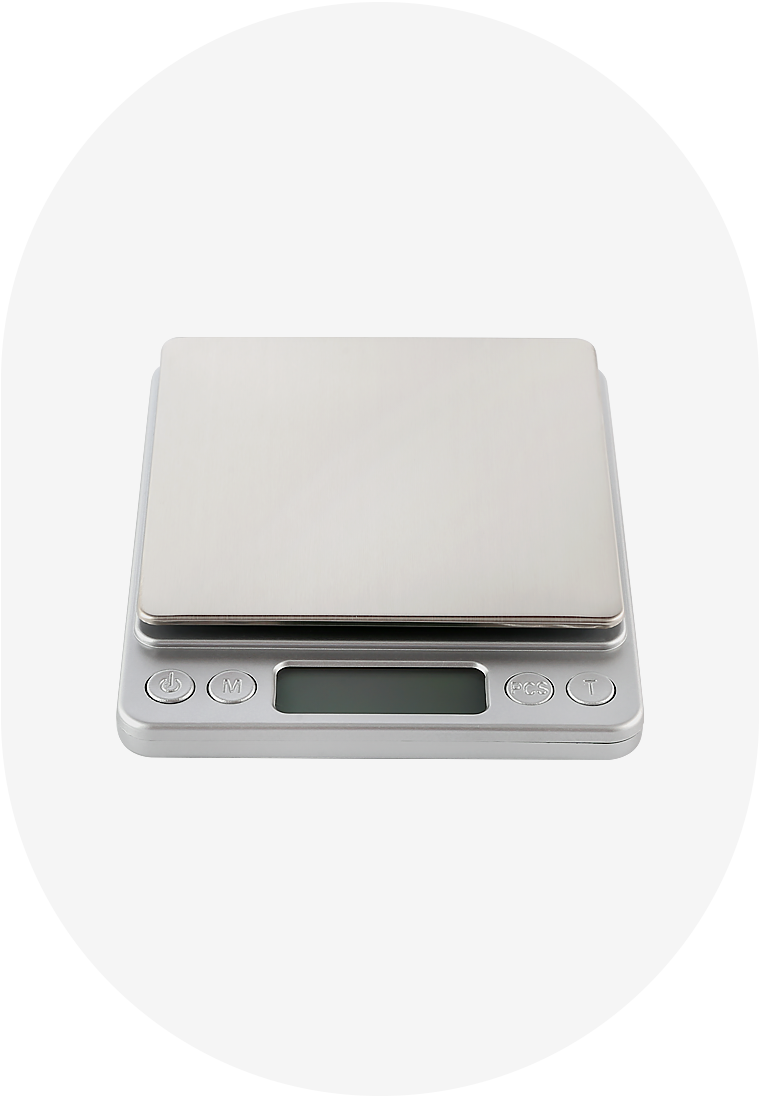

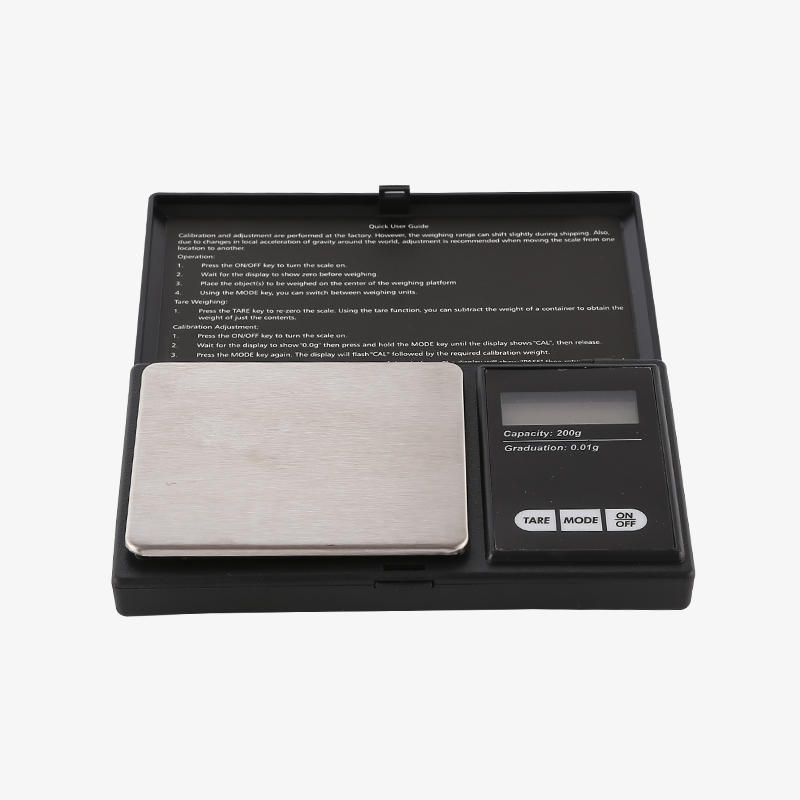

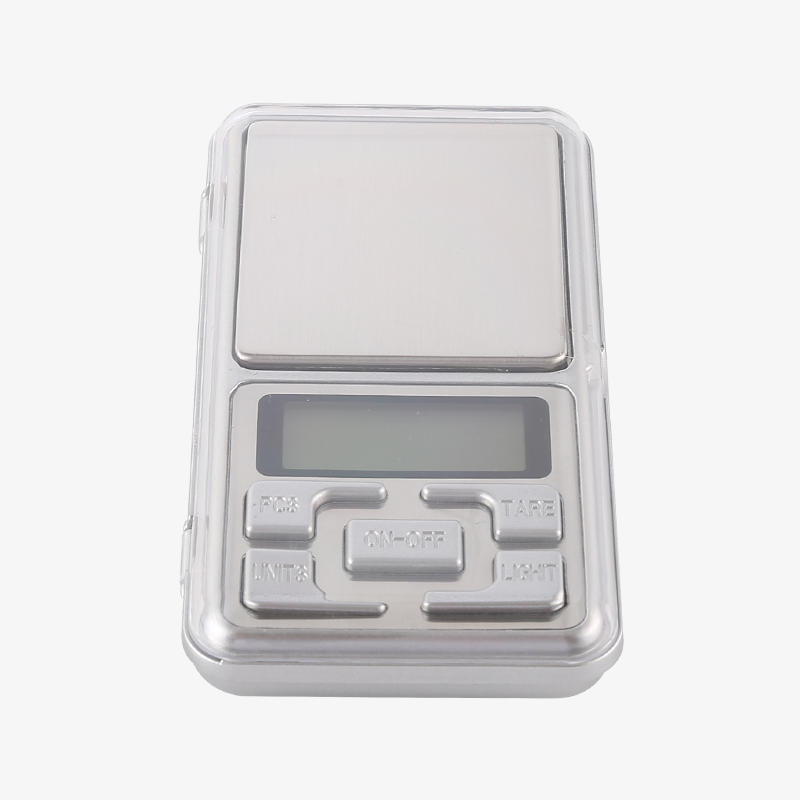

Display and Control Panel Components: Visibility and Accessibility

The materials employed in the display and control panel components are essential for ensuring visibility, accessibility, and longevity. Transparent and durable materials, such as high-impact polycarbonate or tempered glass, are often used for displays to withstand potential impact and harsh working conditions. Control panels may utilize materials that resist chemical exposure or abrasion, ensuring that buttons and interfaces remain functional over extended periods of use. The careful selection of materials for these components contributes to the overall durability and user-friendliness of the electronic crane weighing scale.

Environmental Sealing: Safeguarding Against Contaminants

Electronic crane weighing scales often operate in environments where exposure to dust, moisture, and other contaminants is unavoidable. The materials used for environmental sealing play a crucial role in safeguarding sensitive components from these elements. Seals made of materials like silicone or rubber with appropriate IP (Ingress Protection) ratings create a protective barrier, preventing the ingress of dust and moisture. The effectiveness of these seals depends on the resilience and compatibility of the chosen materials with the scale's operating environment.

Overload and Shock Protection: Preserving Structural Integrity

Electronic crane weighing scales must withstand sudden shocks and overloads without compromising their structural integrity. Materials that offer high-impact resistance, such as hardened steel or alloys with shock-absorbing properties, are often incorporated into critical components. These materials help the scale withstand the dynamic forces exerted during the lifting and lowering of heavy loads, ensuring that it remains operational and accurate even under challenging conditions.

Industrial environments can experience temperature variations, from cold to scorching heat. The materials chosen for electronic crane weighing scales must be capable of withstanding this temperature without compromising performance. Components made from materials with high thermal stability, low thermal expansion coefficients, and resistance to temperature-induced degradation ensure that the scale maintains accuracy and functionality across a broad range of operating temperatures.

The material choices made in the production of electronic crane weighing scales play a pivotal role in determining their durability, accuracy, and overall performance in demanding industrial settings. Manufacturers must navigate these material considerations carefully, selecting materials that not only meet performance requirements but also ensure the longevity and resilience of electronic crane weighing scales in the dynamic world of industrial weighing and material handling.

عربى

عربى Español

Español