Sentian Pet is based on natural materials, and its products are widely used in solid wood, sisal, seaweed, corn leaves and other environmentally friendly materials, which are deeply loved by customers and consumers.

Digital spring scales are commonly used in various industries and applications to measure the weight or force exerted on an object. These scales utilize a suspended spring mechanism and digital technology to provide accurate and precise measurements. However, like any other electronic device, digital spring scales can experience improper operation due to various factors.

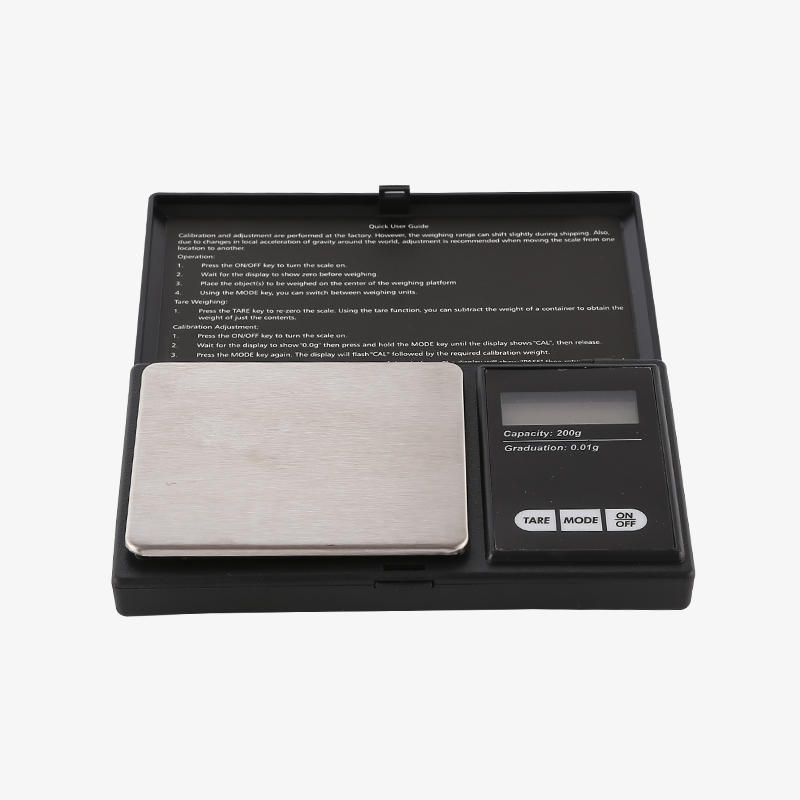

1. Calibration Issues

Digital spring scales need to be properly calibrated to ensure accurate and reliable measurements. If a digital spring scale is not calibrated correctly or requires recalibration, it can lead to improper operation. Calibration involves setting the scale to zero and providing accurate readings for specific weights or forces.

Improper calibration can occur due to mechanical wear and tear of the scale, incorrect adjustment knobs, or a lack of routine calibration checks. Inaccurate calibration can result in incorrect measurements, leading to inconsistent or unreliable results.

To rectify this issue, it is important to follow the manufacturer's guidelines for calibration and routine maintenance. Regular calibration checks should be performed using calibrated weights or known-force sources to ensure accurate readings.

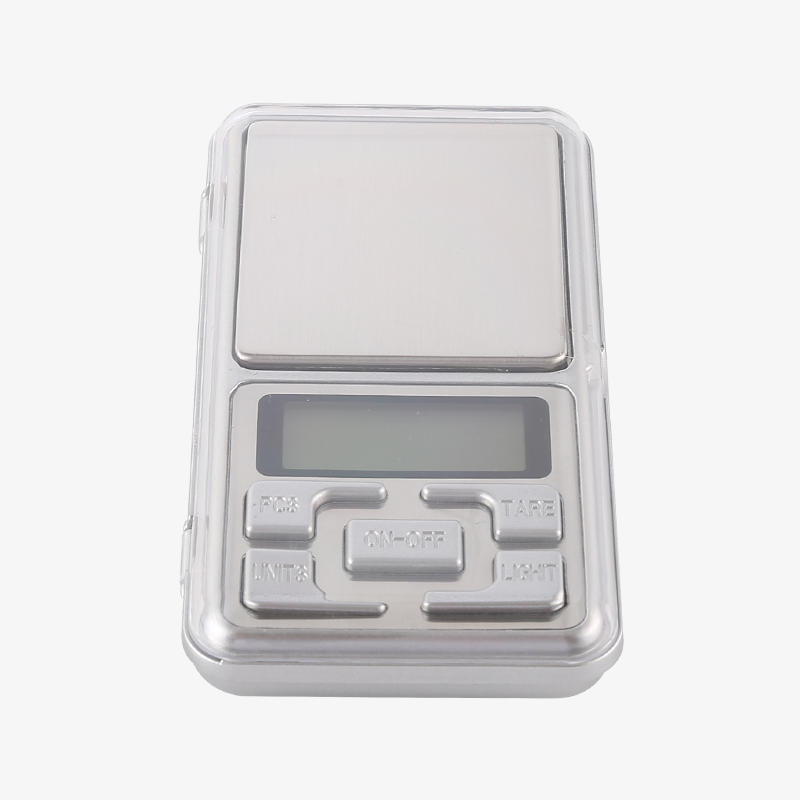

2. Overloading or Underloading

Digital spring scales have specific weight or force capacity limits. Exceeding these limits by overloading the scale or applying insufficient force by underloading can cause improper operation.

Overloading the scale can strain the spring mechanism beyond its capabilities, causing inaccuracies in measurements or even damaging the internal components. On the other hand, underloading can result in insufficient deflection of the spring, leading to inaccurate and inconsistent readings.

To prevent these issues, it is essential to understand the weight or force capacity of the digital spring scale and use it within the specified range. If higher weight or force measurements are required, it is advisable to use a scale with a higher capacity.

3. Environmental Factors

Environmental conditions can also affect the proper operation of digital spring scales. Factors such as temperature, humidity, and vibrations can introduce errors or inconsistencies in measurements.

Extreme temperatures can affect the accuracy of the spring mechanism or the digital components of the scale. Similarly, high humidity levels can cause corrosion or condensation, leading to malfunctioning or erratic readings.

Vibrations from nearby machinery or equipment can introduce variations in the measurements, especially for sensitive or delicate scales. Additionally, electromagnetic interference from nearby electronic devices can affect the digital display or disrupt the internal circuitry.

To mitigate these environmental factors, it is crucial to operate digital spring scales in controlled environments with stable temperatures and low humidity. Avoid placing the scale near vibrating or magnetic sources and ensure proper shielding from external interference.

4. Battery Issues

Digital spring scales are powered by batteries, and improper battery management can result in operational problems. Low battery levels or poor battery connections can lead to inconsistent or inaccurate readings, intermittent display issues, or complete power failure.

Regular battery maintenance is necessary to ensure the uninterrupted operation of digital spring scales. This includes checking and replacing batteries as needed, ensuring proper insertion and tight connections, and monitoring battery levels to prevent unexpected shutdowns during use.

In some cases, using low-quality or expired batteries can also affect the performance of the scale. It is important to use fresh and reliable batteries from reputable manufacturers to ensure optimal performance.

5. Mechanical Damage

Digital spring scales can experience mechanical damage during use or transportation, leading to improper operation. Dropping the scale, mishandling the weighing platform, or subjecting it to excessive force can cause misalignment or deformation of the internal components.

Mechanical damage can result in inaccurate measurements, erratic readings, or dysfunctional display screens. It is crucial to handle digital spring scales with care and follow proper operating procedures to prevent any mechanical damage.

عربى

عربى Español

Español