Sentian Pet is based on natural materials, and its products are widely used in solid wood, sisal, seaweed, corn leaves and other environmentally friendly materials, which are deeply loved by customers and consumers.

Dial spring scales are mechanical devices used for measuring weight or force. They are commonly found in various applications such as warehouses, laboratories, and kitchens. These scales provide a quick and accurate measurement of weight and are known for their durability and reliability. Dial spring scales are vital instruments used in a wide range of industries for measuring weight or force. The different types of dial spring scales, such as the platform, hanging, tension, compression, and pocket, provide diverse means of obtaining accurate measurements. Whether in a warehouse, laboratory, or kitchen, dial spring scales are trusted for their durability, reliability, and ease of use. With their simplicity and efficiency, dial spring scales continue to be an essential tool for weight and force measurement.

1. Platform Dial Spring Scale:

The platform dial spring scale is a popular type of dial spring scale used in many industries. It consists of a flat platform on which the object to be weighed is placed. The scale's dial, which is typically graduated in pounds or kilograms, displays the weight. The platform dials spring scale is capable of weighing heavy objects due to its strong spring mechanism and robust construction. It is commonly used in warehouses and construction sites for weighing bulk materials like sacks of grain, hardware, or building materials.

2. Hanging Dial Spring Scale:

The hanging dial spring scale, as the name suggests, is designed to be suspended from a fixed point. It consists of a spring and a hook from which the object to be weighed is hung. The weight is indicated by a dial that can be read easily. This type of dial spring scale is advantageous when it comes to measuring the weight of objects that are difficult to place on a platform scale, or when portability is required. For example, it is commonly used in fishing and shipping industries to measure the weight of fish catch or packages.

3. Tension Dial Spring Scale:

The tension dial spring scale is specifically designed for measuring the tension or force applied to an object. It consists of a spring mechanism enclosed in a protective casing with a hook on one end and a dial on the other end. The dial indicates the amount of force being measured in units such as pounds or newtons. This type of dial spring scale is widely used in engineering, construction, and material testing industries for measuring the tension in cables, wires, and other structural components.

4. Compression Dial Spring Scale:

The compression dial spring scale is the counterpart of the tension dial spring scale. It is designed to measure the compression or force applied to an object. This type of dial spring scale is commonly used in industries such as manufacturing, automotive, and agriculture. It is useful for measuring the force exerted by compressible materials like springs, rubber, or sponge. The dial displays the amount of force being applied, allowing for precise measurements.

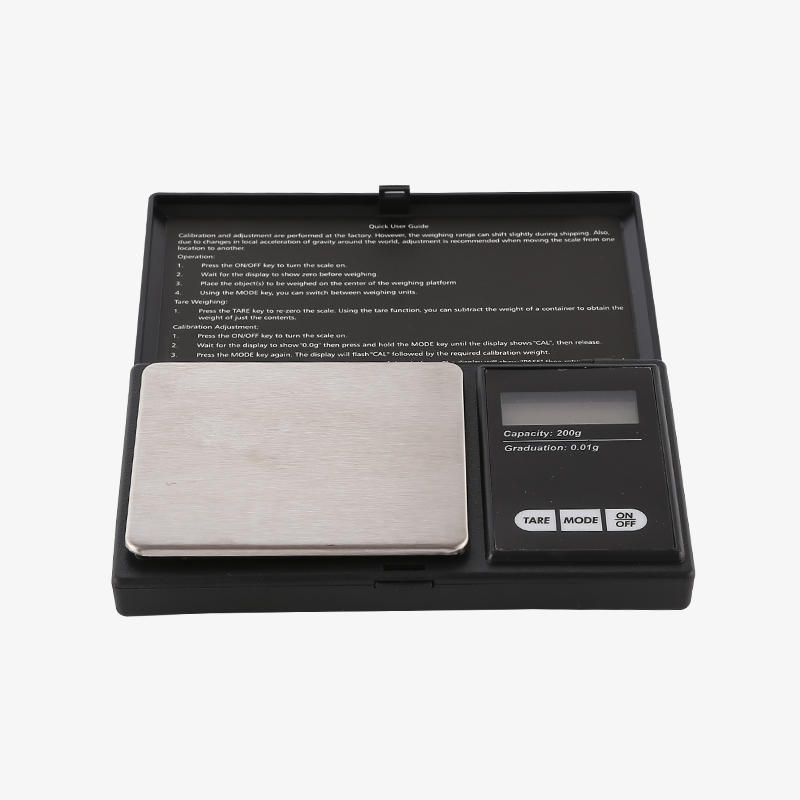

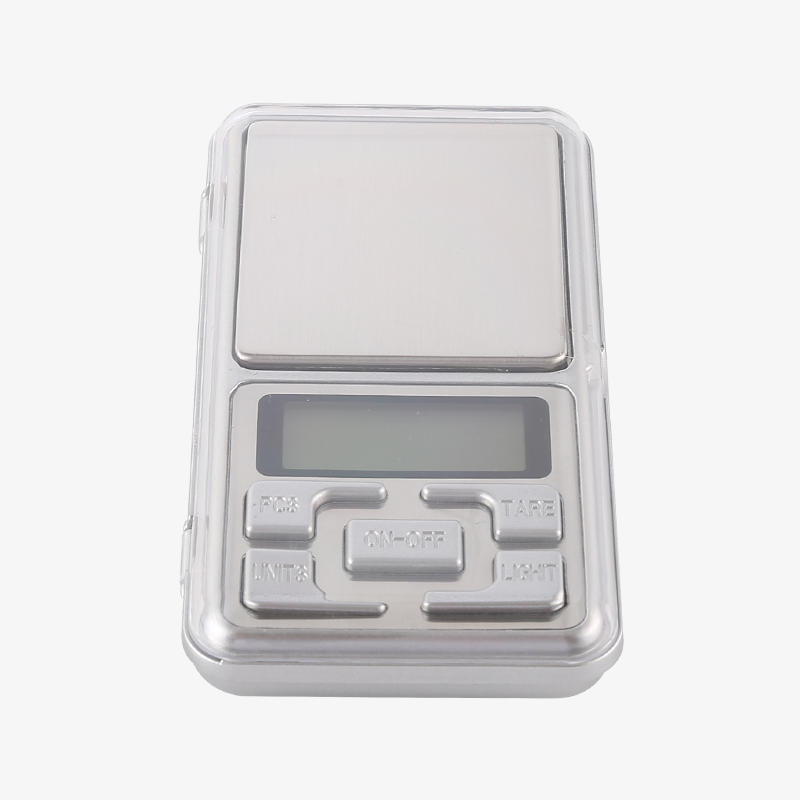

5. Pocket Dial Spring Scale:

The pocket dial spring scale is a compact and portable version of the dial spring scale. It is designed to be small enough to fit in a pocket or bag, making it convenient for on-the-go weighing. This type of dial spring scale typically has a smaller capacity compared to other types, but it still provides accurate measurements for everyday uses. It is commonly used by travelers, outdoor enthusiasts, and in the culinary industry for portion control and recipe measurements.

Each type of dial spring scale has its unique features and benefits, but they all operate on the same basic principle. The scales work by utilizing a spring that is calibrated to exert a certain amount of force when compressed or stretched. As weight or force is applied to the scale, the spring expands or contracts, causing the dial to move and indicate the measurement.

To ensure accurate readings, dial spring scales need regular calibration. This involves adjusting the scale to match predefined reference weights or forces. Calibration can be done manually or by using external calibration equipment. Regular calibration is essential for maintaining the accuracy and reliability of the scale.

عربى

عربى Español

Español